|

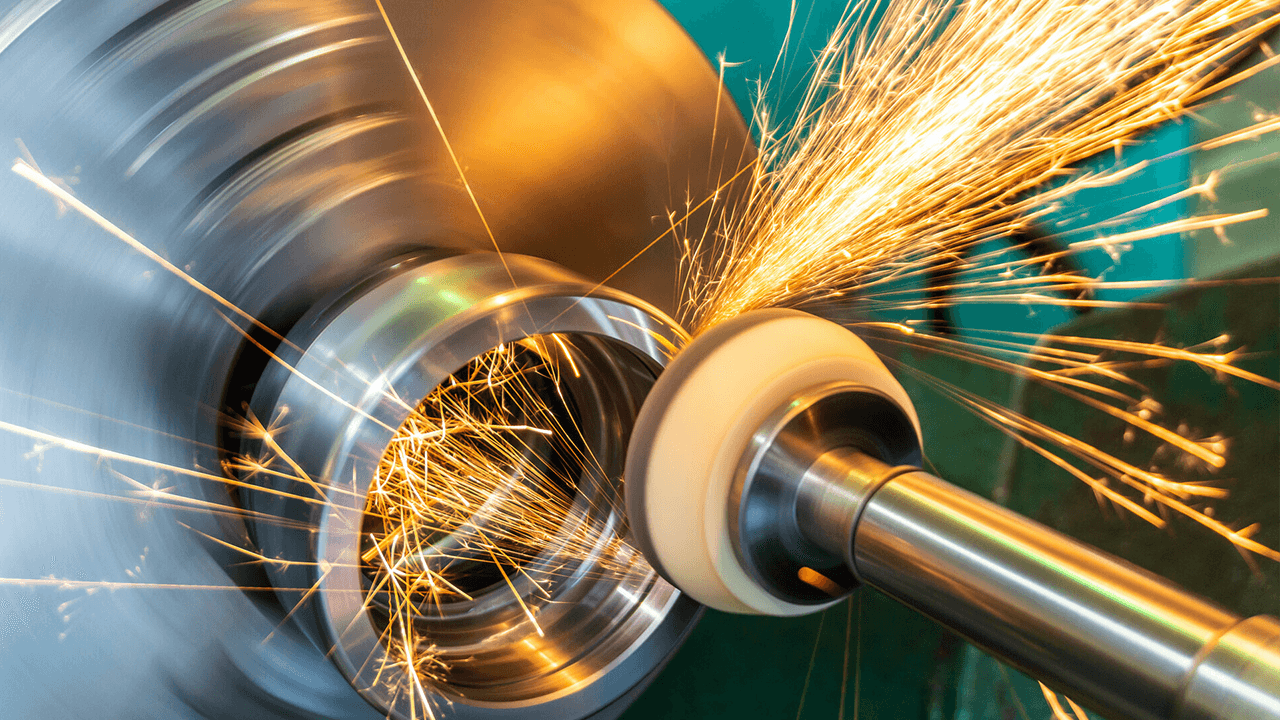

At present, most of the grinding machines on the market are processed by using ultra-high-speed rotating grinding wheels, and only a few are processed using other types of abrasive tools such as oilstones and abrasive belts, or using free abrasives, such as super finishing Machine tools, honing machines, grinding machines, belt grinders, polishing machines, etc.

Feature requirements: According to the movement characteristics of different grinding machines and different process requirements, the following requirements are required for the electric drag and control: 1. Due to the reasons of the grinding machine, the grinding wheel generally does not require speed regulation, only one A three-phase asynchronous motor can be dragged, and the direction of rotation is relatively simple. And when the required capacity is large, the Y-delta step-down start method can also be used. 2. To ensure the processing accuracy, it is necessary to make its operation as smooth as possible, and ensure that the inertia of the worktable is as small as possible when performing reciprocating reversal movement. As a result, hydraulic transmission is often used to realize the reciprocating movement of the worktable. And the horizontal feed of the grinding wheel box. Daily maintenance Grinding machines usually need to be equipped with special personnel to be responsible for maintenance and repairs. At the same time, the grinders must be regularly inspected to ensure that the machine tool is in good working condition. 1. When the operation of the machine tool is completed, it should be wiped clean and oiled for maintenance everywhere on the machine parts, especially the sliding parts. 2. Always clean the grinding waste from all parts of the grinder. 3. For the important joint parts of the machine tool, anti-rust oil should be applied. Matters needing attention after using grinder: 1. Before the grinding operation, the balance of the grinding wheel should be corrected 2. The principle of selecting grinding wheel during operation should choose the most suitable grinding wheel with different work piece materials and hardness. 3. A thin oil film should be applied to the spindle end of the grinding machine and the flange of the grinding wheel to prevent the generation of rust. 4. Pay attention to the direction of rotation of the spindle. 5. It is forbidden to use air guns and air guns to clean the work pieces and machines. 6. Before operation, check whether the oil window and oil path of the grinder are smooth. 7. The vacuum box and filter steel need to be cleaned once a week. 8. If the suction power of the grinder is too weak, it is necessary to check whether there is clogging in the dust suction pipe. 9. The dust suction pipe should be cleaned from time to time, otherwise it will easily cause burning when there is too much dust. Grinding machine maintenance: The surface of the permanent magnetic casting chuck or electromagnetic chuck is the basis for whether the grinding accuracy of the work piece can meet the requirements, and it should be regularly maintained and maintained. If the precision of the work object does not reach the standard or the surface of the disk is damaged, the surface of the disk needs to be ground again, and the accuracy of the surface of the disk has been sought to meet the requirements, to ensure the grinding accuracy of the work piece. Maintenance of grinder lubrication system: The lubricating oil of the new grinder should be replaced after one month of use. The frequency of subsequent replacement is 3-6 months. There is a drain plug under the oil tank, which can be used reasonably. At the same time, when changing the oil, pay attention to cleaning the tank and the filter together. Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly