|

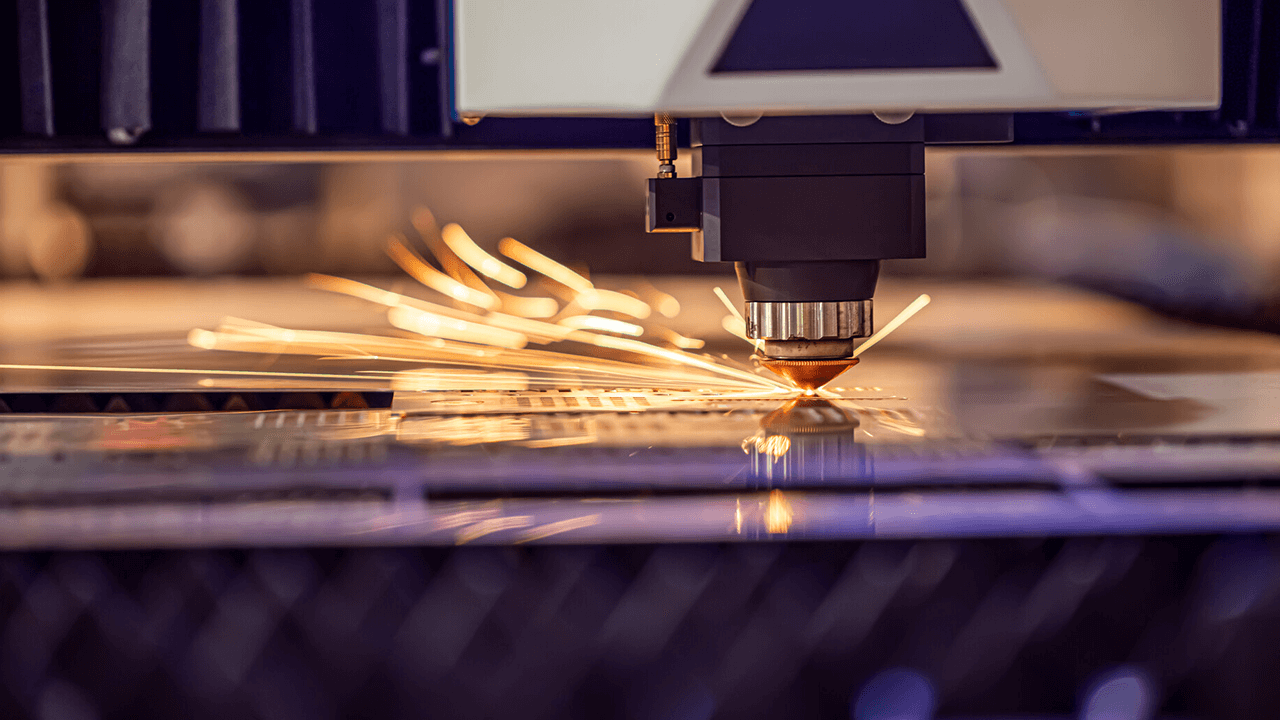

Laser cutting works by directing the output of a high-power laser through optics to focus the resulting laser beam. The cutting process is melted by aligning its materials. The laser cutting technology can have a high-quality surface finish cutting edge, which is used in industrial production, cutting flat materials and pipe materials. Compared with the traditional cutting process, the laser cutting technology can make the laser cutting more precise, the slit width is smaller, and the heat-affected zone is smaller, and the relatively complicated shape or the small hole cutting can be performed. Laser cutting is a thermal separation method that cuts many different materials efficiently, quickly and accurately. Laser is everything. After the laser processing is completed, the finished work piece can be removed immediately without reworking. If the laser illuminates the material at low power, only one layer is removed (and thus etched). If you increase the power, the laser beam will penetrate the material. The laser can cut a wide variety of materials such as acrylic, wood, laminate, film, signage, paper and more. There are some different methods of cutter using lasers, with different types used to cut different material. Some of the methods are vaporization, melt and blow, melt blow and burn, thermal stress cracking, scribing, cold cutting and burning stabilized laser cutting. Article Source: esabna

Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly