|

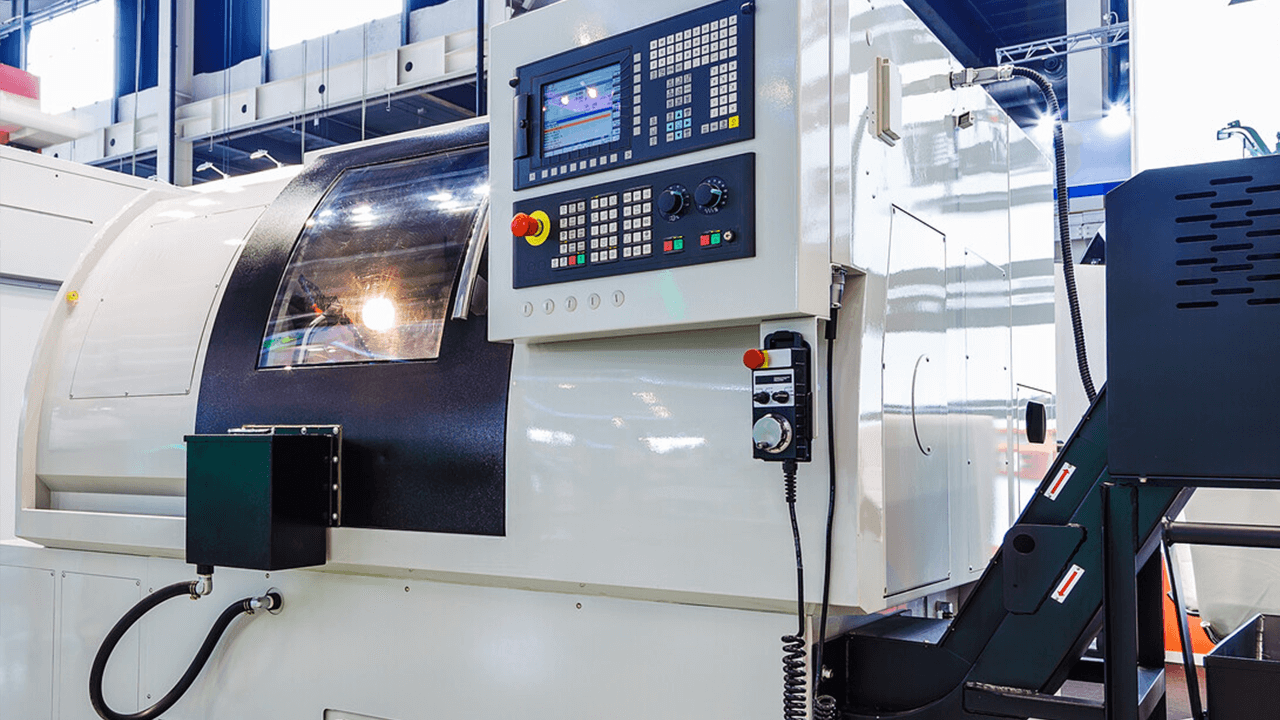

A milling machine is a tool in the metal industry that has numerous functions. Each machine has a cutter that operates at a various range of speed so you can form the required shape. With its adjustable speed feature, each milling machine can be regulated for a more precise cut. The machine is capable of handling multiple tasks such as carving, threading, milling, drilling, and cutting.

There are several types of milling machines, each with varying functions based on standard criteria. Manufacturers often name the different machines according to the kind of control, number of axis present, orientation of the spindle, size of the tool, its purpose, and source of power. While there are several varieties of milling machines available today, they essentially serve the same functions but use different terminologies. Below is the list of seven types of milling machines.

With the vast classifications of milling machines, you need to choose the one you need according to how you intend to use it. However if you find it difficult to decide, do not hesitate to seek the help of a specialist who can help you select the one that will give you maximum benefits. Article Source: Ricardo Barbosa Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly