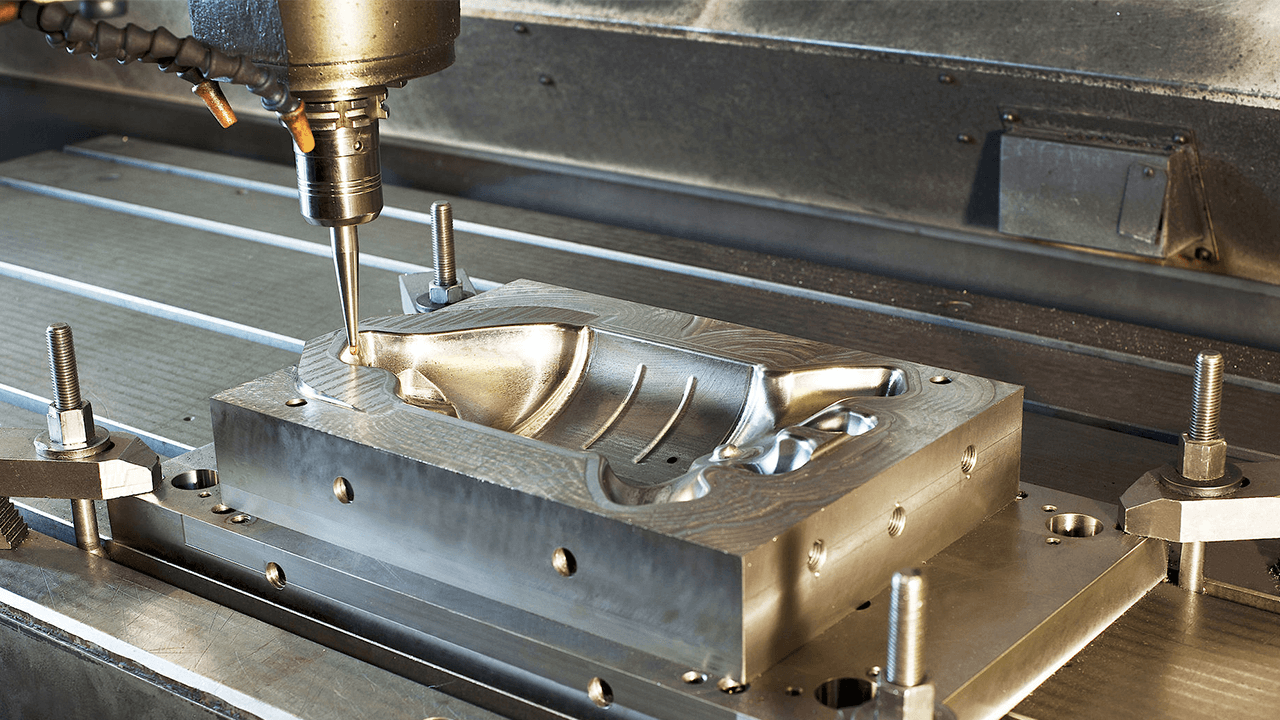

Four New High-Performance Milling TechniquesWhat is milling?

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done in varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes. 1. Rough up to 80% Faster with Adaptive Milling Whether dealing with a mold cavity or a prismatic shape, the fastest way to remove material is often with NX CAM’s high-speed roughing cycle – Adaptive Milling. When milling conventionally with a spiral collapsing pattern, after milling down the adjacent regions of a protruding part feature you are often left with work-hardened surfaces that are difficult to program and machine to final form, forcing a slower machining process with reduced tool life. With Adaptive Milling, the toolpath automatically maintains a consistent chip load which results in faster, smoother cutting. 2. Spiral Finishing Cuts Cycle Times while Generating Extremely Fine Surface Finishes Spiral Finishing also reduces cycle time by cutting as much material as possible with continuous in-cut toolpaths interrupted only by retract and engage motions to reach different workpiece features. Spiral Finishing is easy to program in NX because you just have to select the areas to be finished and the tool, and then the software does the rest. Besides being faster, the continuous toolpath results in smoother surfaces. It is exceptionally applicable to micromachining applications. 3. Flow Milling Enables Machining with Extraordinary Tolerances and Surface Finishes Flow Milling takes achievable 3D finishing tolerances to a whole new level, which can be measured in microns. Flow milling should be of particular interest to mold makers because it allows you to machine features, such as corners of pockets, that otherwise would have to be finished with sinker EDM, which can be a time-consuming process. 4. Planar Deburring Automation Saves Valuable Programming Time Deburring is one of those nagging operations that can be difficult and time consuming to program in complicated parts which is why so many shops continue to deburr with post machining processes. Planar Deburring is a new NX function that greatly simplifies the programming process allowing a fully deburred part to be completed right in the machining cycle. It’s particularly useful for parts such as investment castings where edges must be cleaned up as well as other machined features. With these innovative cutting methods, you can achieve levels of accuracy, surface finish, and efficiency on a machining center that were unthinkable only a few years ago. Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly