|

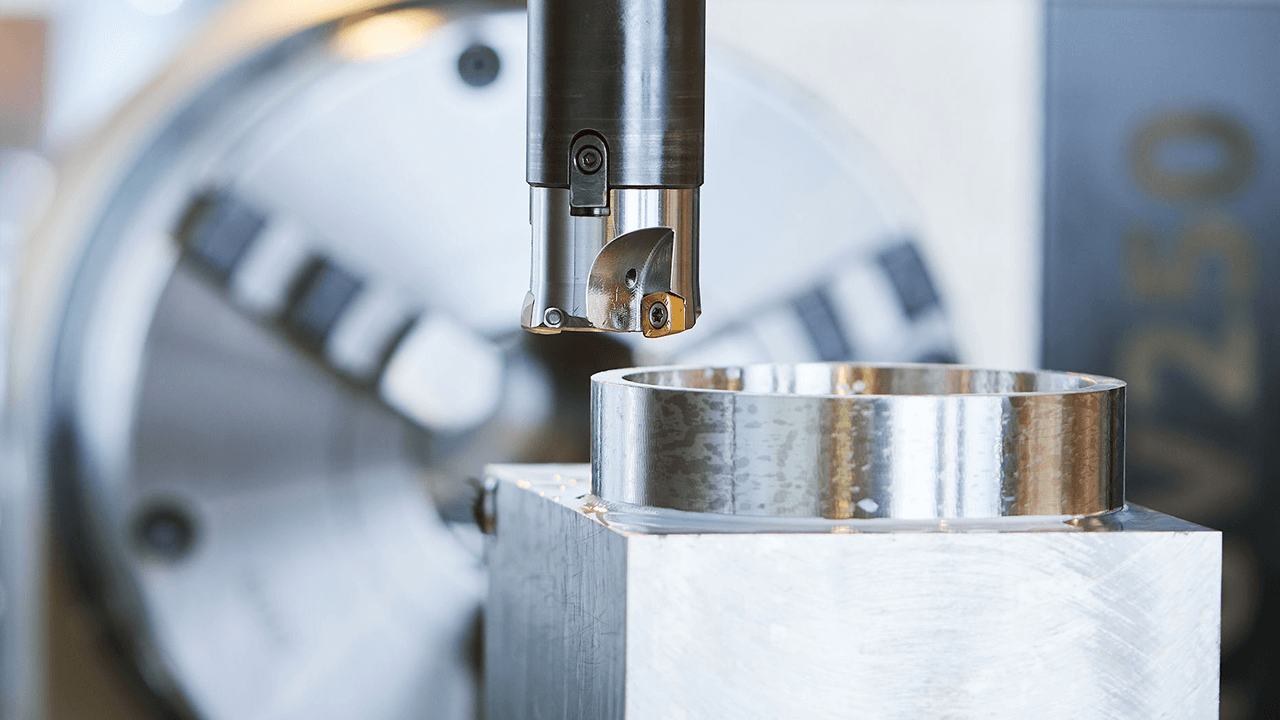

Speaking of what the CNC machining center can do, the two most basic functions are roughing and smoothing. What do these two professional mechanical terms mean? Roughing refers to rough processing of rough material. After roughing, the excess part will be removed, leaving only the finishing allowance. The light knife refers to the fine processing to improve the surface finish of the work piece. General rules of machining path for roughing and smoothing When performing roughing, select the largest possible tool under the maximum load of the CNC machining center, the largest possible feed, and the fastest possible feed. In the case of the same knife, the feed is inversely proportional to the amount of feed. A load of the general CNC machining center is not the main problem of roughing. The principle of tool selection is mainly based on whether the two-dimensional angle and three-dimensional arc of the product are too small. After selecting the tool, the tool length is determined. The principle is that the tool length is greater than the machining depth. For large workpieces, whether the chuck interferes should be considered. A light knife generally refers to a laser tool, which uses the characteristics of the laser to focus. The energy density of the spot at the focus point is extremely high, enough to melt or even vaporize the surface of any object, and cut the material like a tool. The purpose of the light knife is to meet the processing requirements of the workpiece surface finish and reserve an appropriate margin. Similarly, the smooth knife uses the largest possible knife, as fast as possible, because the fine knife takes a long time, with the most suitable feed and feed. Under the same feed, the larger the lateral feed, the faster. The feed amount of the curved surface is related to the smoothness after processing. The feed size is related to the surface shape of the curved surface. Without damaging the surface, leave the smallest margin, Use the largest knife, the fastest speed, and proper feed. Precautions for roughing and smoothing CNC machining center tool 1. Tool clamping The cutting tool diameter of the rough and smooth knife should be above 10mm, and the clamping length should not be less than 30mm; the diameter below 10mm, the clamping length should not be less than 20mm. The tool should be clamped firmly to prevent collision with the tool and direct insertion into the work piece. 2. Use of Horn If the work piece is large and the clamping height is not enough, and the wire is not allowed to lock the wire at the bottom, the code iron is used for clamping. This kind of clamping requires two times clamping, first code the four corners, process the other parts, and then code the four sides and process the four corners. During the second clamping, do not let the work piece loose, first, loosen, and then loosen. You can also code both sides first, and process the other two sides. 3. Processing tool selection It is easy to wear, and it is used for thickening copper and small steel materials. White steel knives should be used; when high-speed cutting, purple knives are not easy to wear; tungsten steel knives are used for steel corners or smooth knives. Roughing and smoothing are the two most important and basic functions of the CNC machining center. They must be firmly grasped in the daily machining process, to better operate the CNC machining center. Reference: kknews

Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly