|

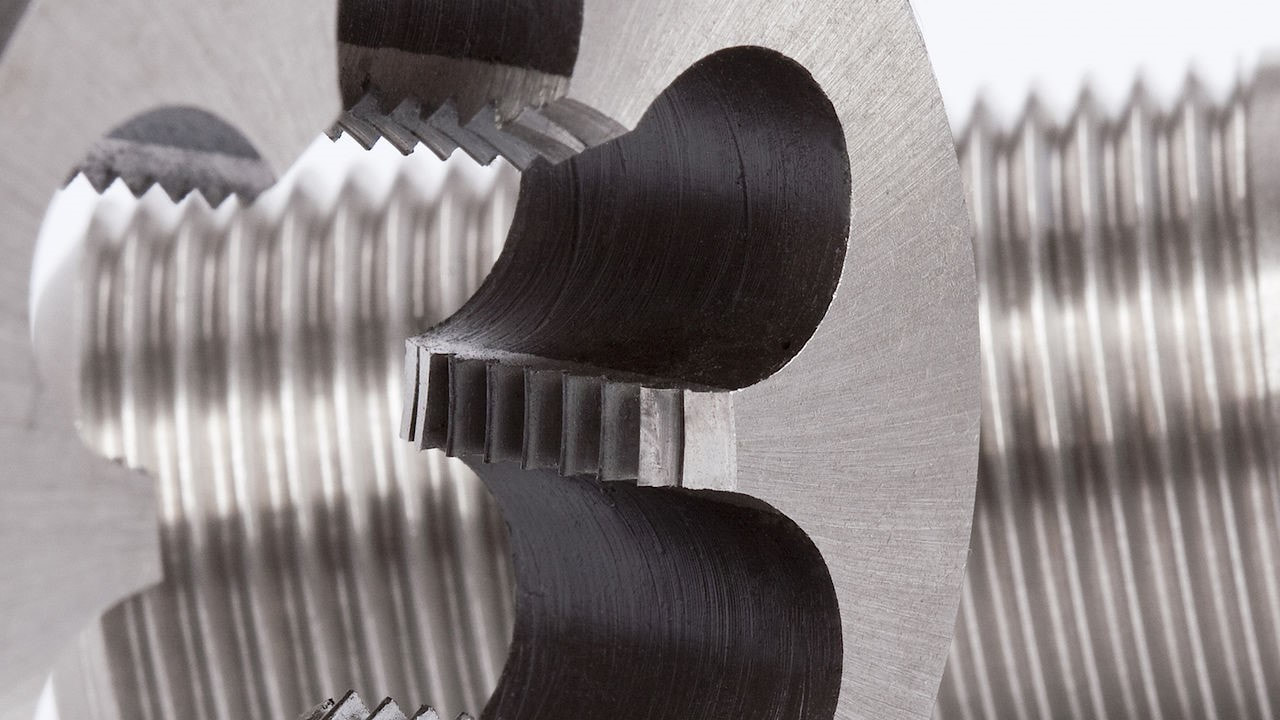

What is a Screw? The screw works under high temperatures, certain corrosion, strong wear, and high torque. The outer surface of the screw is a cylinder with a spiral groove or a cone with a conical spiral groove. The pitch of the screw is generally relatively large, and it is mostly used in plastic molding equipment, such as plastic profile extruders, injection molding machines, etc. Segmentation of the Extruder Screw: The movement of the material in the extruder screw is divided into three sections, so the design of the screw is often carried out in sections. Since each section is a continuous channel, in actual production, as long as the requirements can be met, it is not necessary to divide the screw into three sections. Some screws have only two sections, and some are not divided into sections. When extruding a material with good crystallinity such as nylon, there are only a feeding section and a homogenizing section. For a general screw extruding a soft PVC plastic screw, the entire compression section can be used instead of being divided into a feeding section and a homogenizing section. The segmented type of screw is obtained from experience and mainly depends on the nature of the material. The length of the feeding section can range from 0 to 75% of the total length of the screw. Generally speaking, it is the longest when extruding crystalline polymers, followed by hard amorphous polymers, and the shortest for soft amorphous polymers. The length of the compression section usually accounts for 50% of the total length of the screw, except of course the nylon and soft PVC plastics mentioned above. When extruding polyethylene, the length of the homogenization section can be 20-25% of the total length. However, for some heat-sensitive materials, the material should not stay in this section for too long, and the homogenization section may not be required. Some high-speed extruders take 50% of the length of the homogenization section. Screw Compression Ratio: The compression ratio of the extruder required by various plastics is not fixed and can have a range. Different raw materials require different compression ratios. When extruding soft polyvinyl chloride plastic, if it is a granular material, the screw compression ratio is usually 2.5-3, and if it is a powdery mixture, the compression ratio is 4-5. Choice of screw compression ratio. The compression ratio can be obtained in the following ways:

Screw Aspect Ratio: There are many kinds of plastics used for extrusion molding plastic extruders, and one screw can't mold all plastics. The screw should be designed according to the characteristics of the raw materials, and the commonality of various raw materials should be considered as much as possible so that one screw can extrude several kinds of plastics, which is economically meaningful in industrial production. The anti-thread at the rear end of the screw prevents material leakage. The screw length-to-diameter ratio is L/D, and the screw diameter D refers to the outer diameter of the screw thread. The effective length L of the screw refers to the length of the working part of the screw, as shown in Figure 3-14. The effective length is different from the total length of the screw. The aspect ratio is the ratio of the effective length to the diameter of the screw. The first major diameter of the early spelling machine screw is relatively small, only 12-16. With the development of the plastic molding processing industry, the length-to-diameter ratio of the extruder screw is gradually increasing. At present, the commonly used ones are 15, 20, and 25, and the maximum can reach 43.

Reference: market-prospects

Comments are closed.

|

Categories

All

Machinery FutureShow You Lots of Latest Industry News & Knowledge to Change Your Industrial Vision. A knowledge platform established for industry

Search to Find You Need

|

Proudly powered by Weebly